Application :-

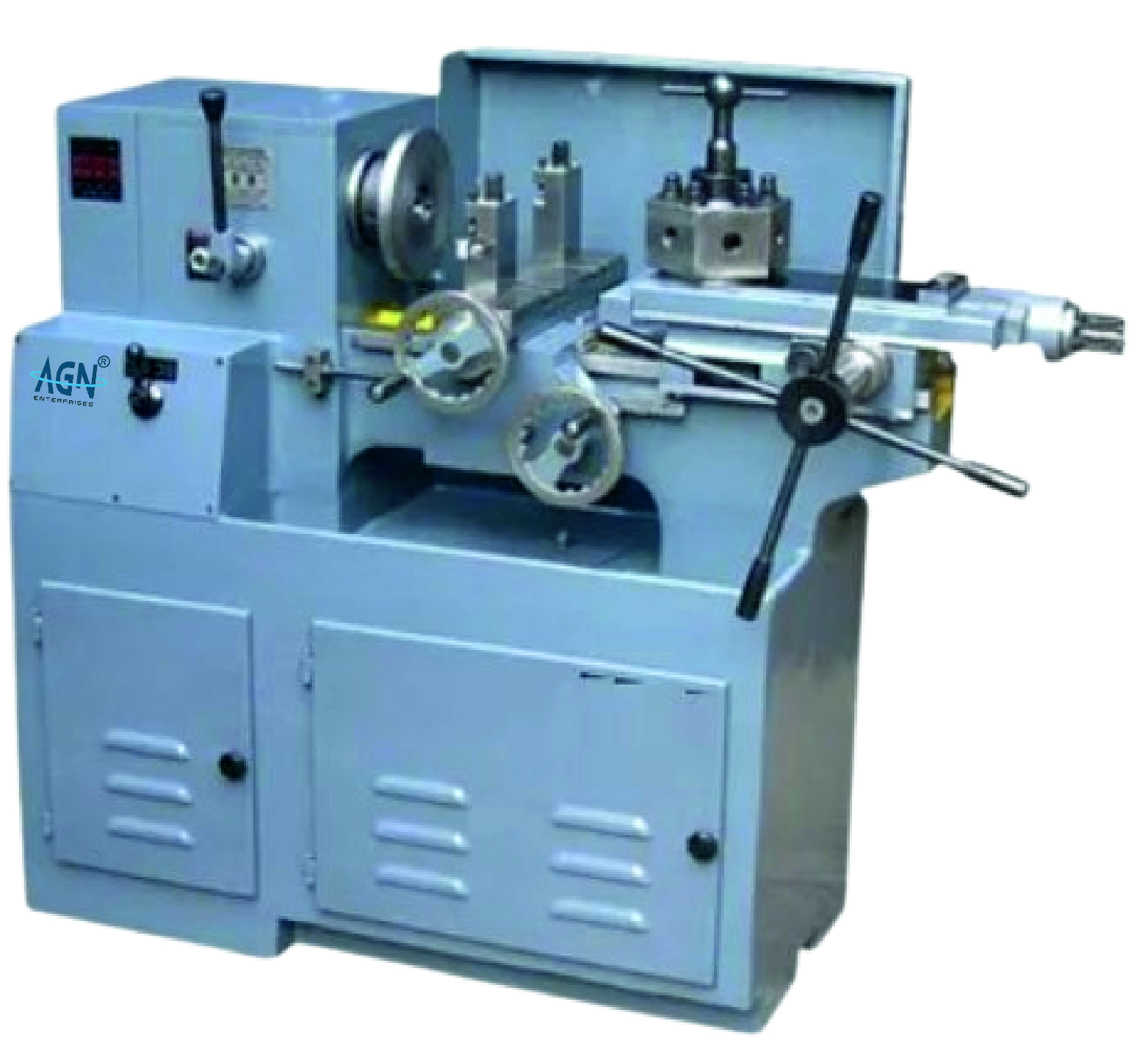

Capstan Lathe Machines, which is an exclusive array of advanced industrial products and is used for chuck work. Its configuration is off without gear box. It is usually brought in purpose of the sanitary fitting industry and is used in drilling, boring, turning, threading, grooving and many more operations. It is price worthy in use as it produces more components with less fatigue. These Capstan Lathe Machines have been designed after performing several quality measures and can be availed from us at economical prices.

Capstan Lathe Machines, which is an exclusive array of advanced industrial products and is used for chuck work. Its configuration is off without gear box. It is usually brought in purpose of the sanitary fitting industry and is used in drilling, boring, turning, threading, grooving and many more operations. It is price worthy in use as it produces more components with less fatigue. These Capstan Lathe Machines have been designed after performing several quality measures and can be availed from us at economical prices.

Definition :-

Capstan Lathe Machine is a cutting-edge precision tool designed for efficient and high-performance machining operations. With its robust construction and advanced features, this model ensures superior accuracy and reliability in turning and shaping metal components. Equipped with a powerful capstan mechanism, it enables rapid tool changes, reducing downtime and boosting productivity. Accommodating a wide range of materials and intricate machining tasks. Its user-friendly interface and modern controls make it an ideal choice for industries demanding precision and speed in manufacturing processes.

Capstan Lathe Machine is a cutting-edge precision tool designed for efficient and high-performance machining operations. With its robust construction and advanced features, this model ensures superior accuracy and reliability in turning and shaping metal components. Equipped with a powerful capstan mechanism, it enables rapid tool changes, reducing downtime and boosting productivity. Accommodating a wide range of materials and intricate machining tasks. Its user-friendly interface and modern controls make it an ideal choice for industries demanding precision and speed in manufacturing processes.

Features :-

– Suitable for batch production or small lot production

– More productive for quick engagement and overlapped functioning of the tools in addition to

faster mounting and feeding of the job and rapid speed change

– Enable repetitive production of same job requiring less involvement, effort and attention of the

operator for Presetting of work speed and feed rate and length of travel of the cutting tools

– Possesses an axially movable index able turret in place of tail stock

– All major castings grade 25 casting

– All gears and shafts in headstocks hardened and ground

– Automatic oil lubricated headstock

– Bed guide ways induction hardened and precision ground

– Color :- Air force blue (Firozi)

Specification :-

Type of head stock : ALL GEARED

Swing over bed : 300mm

Swing over cross slide : 200mm

Center height : 150mm

Holding mechanism : Bar type/ Collet chuck

Collet chuck capacity : 3 mm-40 mm

Range of speed : 300 RPM-1400 RPM

Cross slide travel : 150 mm-200 mm

Turret slide travel : 150 mm- 200 mm

Bore of turret : Hex 25.4 mm

Power : 3 phase, 440 volts, 50 Hz

Length of bed : 1000-1200 mm

Type of bed : Flat type

Size of spindle bore : 50mm

Type of turret : Hexagonal

Front tool post : Four way type

Type of head stock : ALL GEARED

Swing over bed : 300mm

Swing over cross slide : 200mm

Center height : 150mm

Holding mechanism : Bar type/ Collet chuck

Collet chuck capacity : 3 mm-40 mm

Range of speed : 300 RPM-1400 RPM

Cross slide travel : 150 mm-200 mm

Turret slide travel : 150 mm- 200 mm

Bore of turret : Hex 25.4 mm

Power : 3 phase, 440 volts, 50 Hz

Length of bed : 1000-1200 mm

Type of bed : Flat type

Size of spindle bore : 50mm

Type of turret : Hexagonal

Front tool post : Four way type

Accessories :-

– Basic tool and tool kit as per machine

– Allen Key Set-01, Set Spanner Set-01,C/Peg Spanner -02, Tool Post Key-01, Bend Key-01

– Coolant system with motor and swarf tray

– Turret stop (Bar stop)

– Self opening die head with die pieces of standard thread pitches Qty- 06

– Centering tool

– Drill holder and reamer holder

– Turret stopper bolt key

– Set of collets for round bar and hex bar

– Boring bar holder

– Spanner for spindle nut

– Panel board with relay, connector, push button, S/F switch, R/T switch

– Flat steady box tool and roller steady box turning tool

– Gil cane and grease gun

– Rubber mounting pad & Safety Guard

– Initial lubricating, gear box and cutting oil